Compressed Air Usage Analysis & Leakage Identification

The Client

Our customer is a fortune 500 company in the Spices business. Their semi automated plant produces chilli, turmeric and other spice powders.

The Problem

Compressed air production is costly and its wastage results in over consumption of electricity. Compressed air line leakages gets unnoticed and usually gets addressed only when it gets to worst conditions. Customer wanted a solution for detecting and alerting anomalous air consumptions.

Our Approach

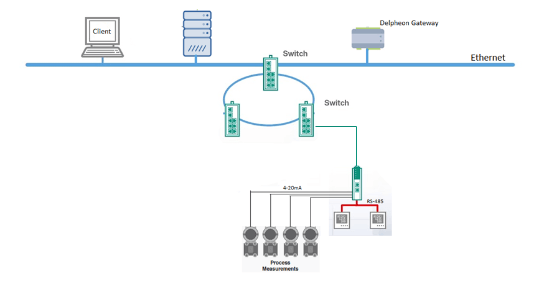

- Compressed air flow meters installed, which works on thermal mass flow principle

- The flow meters connected to the Delpheon IO Module which converts the Modbus RTU protocol to Modbus TCP, thus transporting data over the private LAN

- Delpheon Gateway collects the data from the devices and pushes data to Delpheon platform

- Platform is hosted in an On-premises server with several VM's configured for parallel computing.

- Flow totalization done at the software side

- Specific KPI dashboards for benchmarking and comparisons

- Anomaly detection using AI/ML

- Heatmaps and dynamic charts to easily compare consumption at various levels

Outcome

Easy detection of Leakages

Comparisons enabled against targets

Process wastages gets addressed effectively