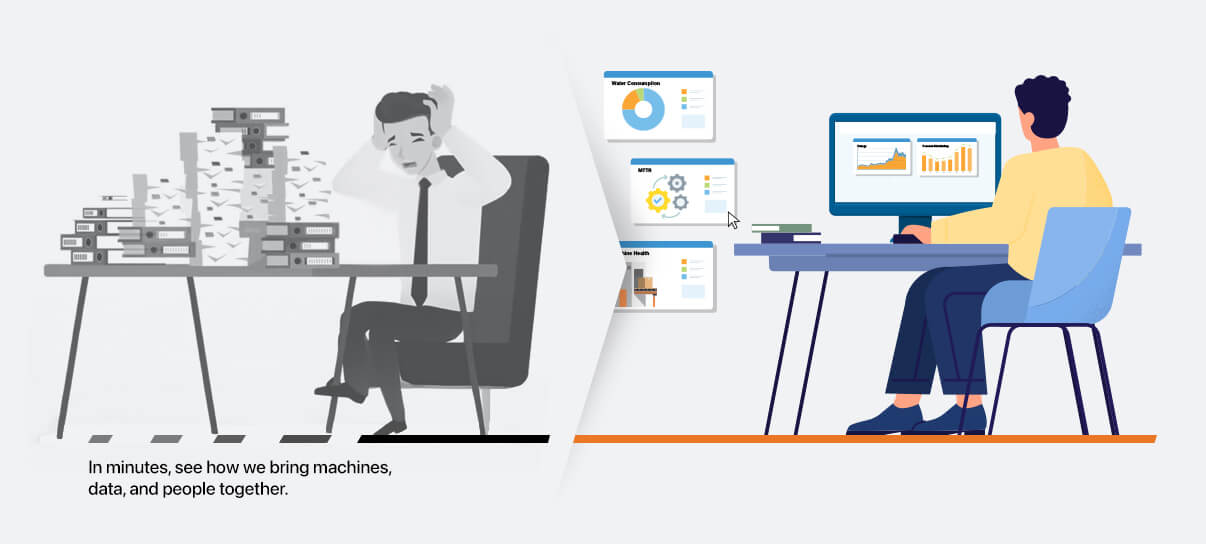

From Data Chaos to

Operational Clarity

See what matters. Act without delays. Scale without limits.

Powered by DelphEon - your trusted partner in realizing the promise of Industry 5.0

Request a demoTechnology for a new era

of Industry and Manufacturing.

Delpheon empowers factories with AI-driven diagnostics, predictive maintenance, and real-time control. Its end-to-end IIoT stack-from smart sensors to analytics-enables seamless digital transformation. Experience smarter, faster, and more efficient operations with minimal manual intervention.

Request a demoCore Components

Delpheon integrates smart sensing, real-time processing, intelligent analytics, and seamless connectivity into one powerful platform.

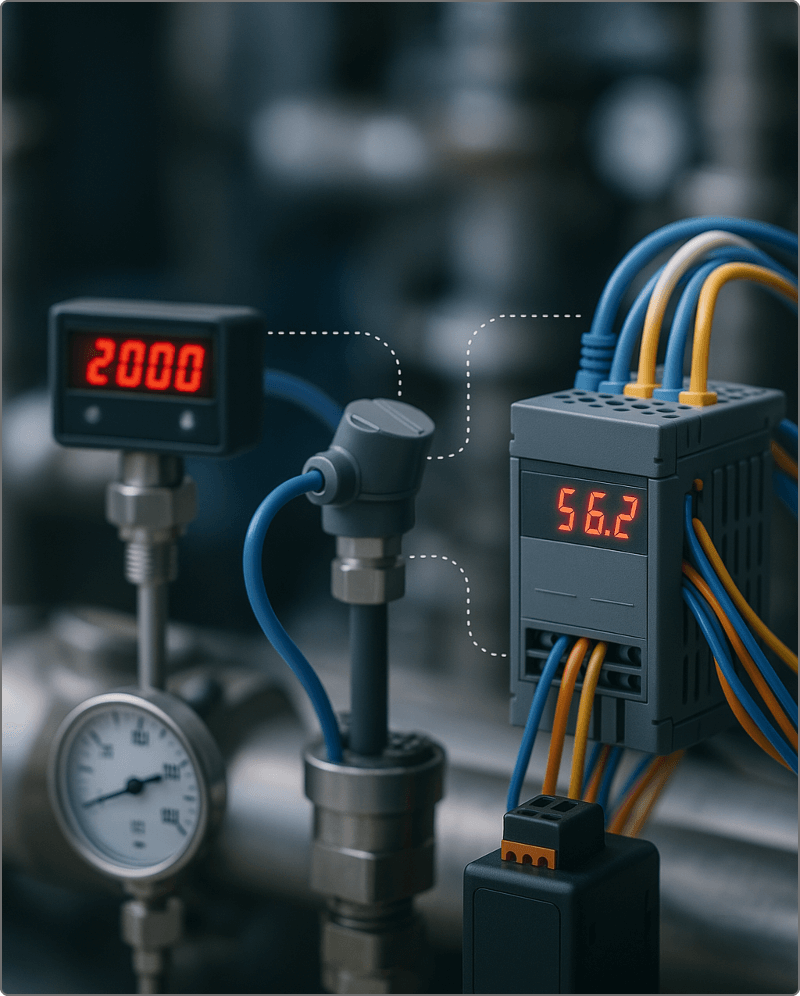

Sensor Packaging

IO Modules

Communication Modules

Data Management Suite

Dashboard Creator

Prediction Engine

Alerting System

Optimization & Control

End to End capability

Delpheon connects your industrial devices, processes real-time data, and delivers actionable insights-ensuring seamless data flow from edge to cloud. Its scalable, secure, and customizable architecture adapts to your unique operational needs.

Devices

Supports data collection from a vast range of sensors, meters, PLCs, and controllers.

Connectivity

Delpheon gateway combined with robust communication modules, ensure reliable data transmission from devices to the platform.

Analytics

The Delpheon platform offers powerful data processing, real-time analytics, and AI/ML to provide actionable insights that drive smarter decisions and reduce operational downtime.

The Delpheon Way

From signals to outcomes.

Untapped Power of Industrial Data

Most factories generate massive amounts of data-but only a fraction is utilized. Delpheon unlocks the hidden potential of this data to drive smarter, faster, and more efficient operations.

Manufacturers are unable to fully utilize the data generated on the shop floor-missing opportunities to uncover inefficiencies, reduce downtime, and improve operational performance.

Industry leaders recognize IoT as a key enabler of competitiveness. Delpheon simplifies this transition, making smart factory implementation faster, easier, and scalable.

Industrial teams report a significant reduction in response time when equipped with real-time insights. Delpheon delivers intelligent, proactive decision-making that accelerates outcomes.

Tailored Solutions

Delpheon's advanced solutions help industries-from manufacturing to utilities-optimize operations, reduce downtime, and boost efficiency through actionable insights.

Logistics and Infrastructure

Loved by customers

You Imagine.

We Build!

We don't just offer technology

solutions — we solve real challenges,

building exactly what you need.

Ready for enterprise scale

Gadgeon is audited and certified by industry

leading Third Party standards