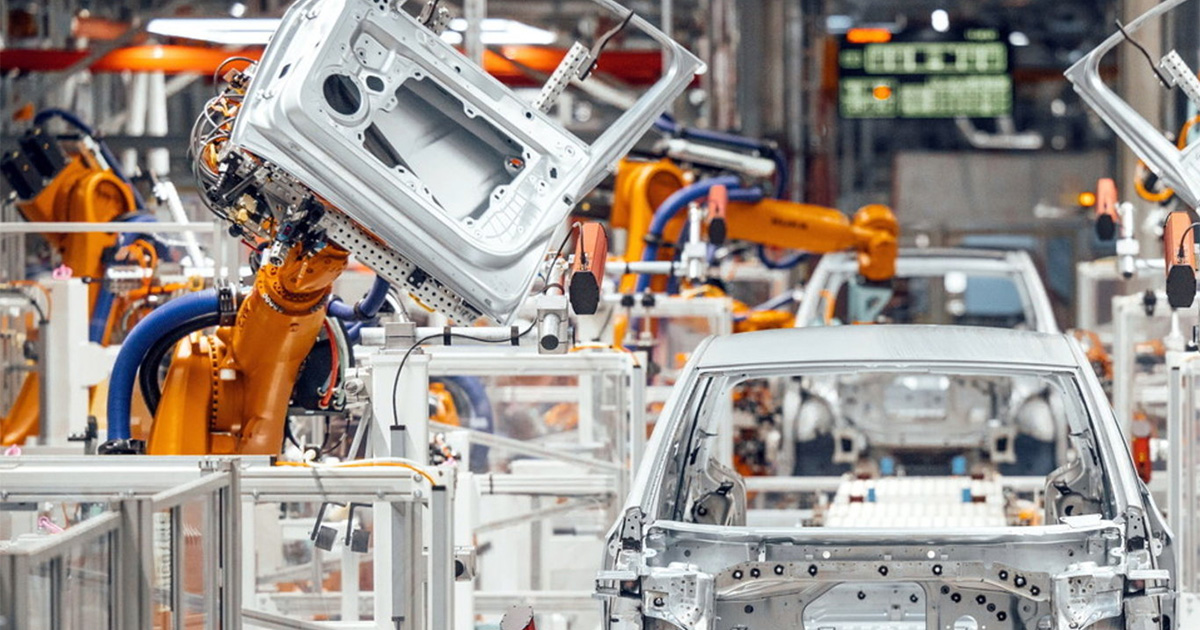

The smart factory concept is experiencing a surge in global adoption, with manufacturers across sectors moving to a flexible, responsive, agile, and integrated ecosystem by leveraging tech innovations like automation and IoT.

Reports expect the smart factory market to exceed $155 billion by 2025, driven primarily by the need to improve operational efficiency, optimize processes, and enable holistic integration through the entire value chain. Energy management plays an increasing influence on manufacturers. Increasing energy costs increase their production costs, hitting the profitability margins. Poor energy monitoring can lead to high operational expenses when overloading machines could lead to breakdowns or under loading reduces productivity. Smart manufacturers need to monitor energy consumed by each piece of machinery and what level will lead to optimal functioning etc. Hence, setting up a smart factory is not just about implementing a handful of connected systems; organizations must be able to drive efforts towards monitoring the energy consumption of their smart factories.

The drawbacks of current monitoring approaches

A shop floor full of automated and connected technological systems is a great sight to behold; they represent a giant leap forward from traditional factory operations to one that constantly learns and adapts to new demands. But given the fact that these systems operate 24x7, they also consume massive amounts of energy – which, when not monitored, can lead to humongous energy bills, operational inefficiencies, and profit margins.

Traditional approaches to energy monitoring are not sufficient to keep up with the age we’re currently in -

- Organizations learn about energy costs only from their utility bills with little or no idea on how to optimize energy to save costs

- With no option to track power consumption in real-time, identifying abnormal patterns of energy use or identifying imminent problems in equipment is impossible

- Excess consumption by some systems and equipment tend to go totally unnoticed, resulting in machine breakdown and massive monthly energy bills

- There is no way to review the energy consumed by a particular machinery or to check consumption during a particular time of the day

- With growing concerns around global warming, climate change, and sustainable energy consumption, organizations find it extremely challenging to discover and reduce carbon footprint.

How IIoT can help

Modern IIoT platforms can set the foundation of smart energy monitoring and management via their unmatched features and capabilities. For instance, Delpheon’s modern, IIoT-based Electrical Power Monitoring (EPM) Solution collects, aggregates, and sends real-time energy data from electrical meters to cloud servers and provides critical insight into energy usage and other defined metrics.

By measuring, visualizing, and optimizing energy usage in real-time, it brings much-needed control over energy consumption – without impacting production speed or quality. Here’s looking at some features an IIoT platform like EPM offers in the realm of smart energy monitoring:

Real-time power monitoring

IIoT-based energy monitoring solutions can enable real-time power monitoring for optimized energy usage. Since they provide insight into energy usage at different operational levels, organizations can always be cognizant of energy consumption and take necessary steps to lower costs and improve profit margins.

Highly scalable

Smart energy monitoring solutions offer high levels of scalability, so organizations can keep up with their growing energy needs without any issues. They allow the enterprises to start with an easy-to-configure, low investment solution and extend to an enterprise-wide power management system – as the need arises – for seamless energy monitoring.

Custom features

Modern energy monitoring solutions also offer several custom features, to meet the unique needs of different businesses. For instance, if you want to measure and monitor partial discharge from your equipment, such a feature can be developed and integrated into your monitoring solution as per your requirements.

System Configuration modules

A smart energy monitoring solution also provides Admin modules that make it easy to customize and configure the solution as per the needs of the business: right from setting up new users, to modifying existing ones, configuring events & alerts, and notification rules to visualizing and analyzing critical parameters via intuitive dashboards and reports.

Accurate fault diagnosis

Modern monitoring solutions are also built with events and alarms for accurate and timely fault diagnosis and analysis. Using the solution, you can get a comprehensive view of energy and power parameters and also receive alerts on faulty or unusual energy consumption values – with traceability to their exact location.

Use from anywhere

Another benefit IIoT monitoring solutions deliver to organizations is their ability to be used from anywhere. To monitor and analyze the power usage of particular equipment, a set of devices, or the entire organization, the users no longer have to physically visit the energy meter. Direct web access allows them to use their Smartphone or laptop and get access to energy metrics from anywhere.

The convergence of the digital and physical world has caused smart factories to mushroom across the world. However, this has also caused the need for smart energy monitoring to reach an all-time high – not just to minimize or optimize energy usage, but also to reduce carbon emission and footprint.

IIoT-enabled smart energy monitoring solutions like Delpheon-EPM can lead to substantial energy cost savings. By collecting energy data from connected systems, they can help in monitoring energy usage in real-time and provide insight into consumption while also flagging events and issues.

If you want to accelerate your Industry 4.0 journey, improve your energy efficiency, reduce operational costs and enhance profit margins, contact us today!