Leveraging Delpheon IoT platform & AI to find anomalous energy consumption

The Client

India based water heater manufacturer with production plants in multiple locations. Manufactures water heaters on a continuous production line, with discrete automation.

The Problem

They didn't have an understanding of their utility consumption pattern. They need to benchmark and enable comparison of the on-going consumption with target levels and take corrective steps if necessary, and required anomalous consumption identification and alerting.

Our Approach

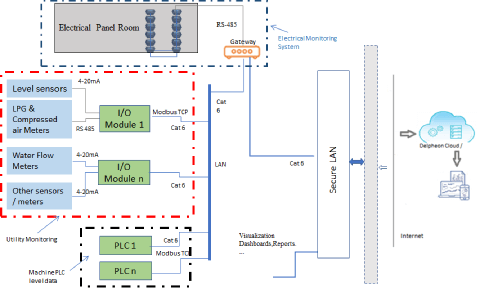

- Networked the energy meters and the gateway at the factory via RS-485 serial loop

- Flow meters connected to IO Module which converts Modbus RTU protocol to Modbus TCP & transport data over LAN which is plugged to gateway downlink

- Delpheon Gateway collects the data from the devices and pushes data to Delpheon platform hosted in Azure Cloud over the secure LAN plugged on its uplink

- Specific KPI dashboards for benchmarking and comparisons.

- Anomaly detection using AI/ML

- Heatmaps and dynamic charts to easily compare consumption at various levels

Outcome

Efficiency gains from digitization and automated collection of data

Managers take appropriate action on inefficient production practices

Energy Centered Maintenance of Machines to keep them in best condition